Automotive

The Complete Guide to Valve Springs

How do you get an engine to produce more power? A short answer is to let it breathe. And this is the job of the valvetrain. Different configurations line different engines. Single Overhead Camshaft (SOHC) engines are found in the likes of legendary 6-cylinder Commodore VLs of the late 1980s (thank you, Nissan), Double/Dual Overhead Camshaft (DOHC) in just about everything sold today and the inline 6 in the Barra being a prime example. OHV or Overhead Valve engines are prized in the HSV GT3 and virtually all American muscle cars. There are a varying number of camshafts and differences as to where they’re located, and different numbers of intake and exhaust valves. Parts differ, but the end goal is the same. Better performance than stock, and more power.

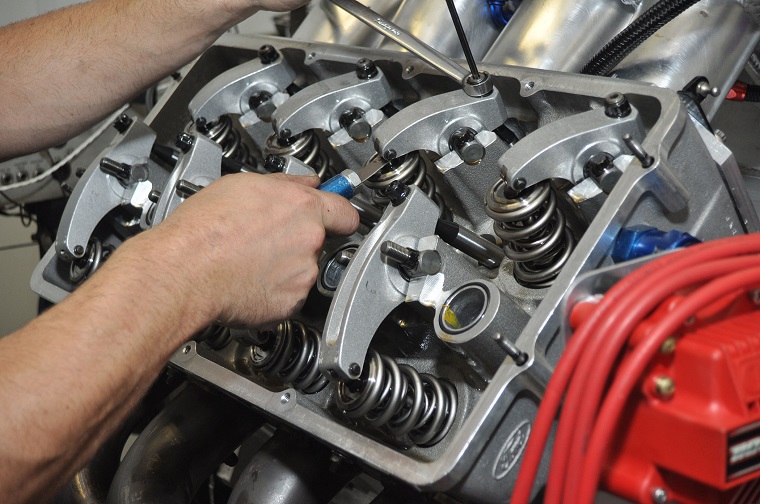

A pivotal part in controlling the valvetrain goes to the valve springs. Valves are mechanically opened by the cam lobes acting on tappets or lifters, and the springs push the valves closed. They do this by applying force to the retainers and retracting the valves back into the cylinder head. The process is repeated thousands of times each minute, and springs are put through varying amounts of pressure during each intake and exhaust stroke. In production cars, this averages around 70 to 90 psi (or 4.8 to 9.2 bar) with the valves closed and 200 psi (13.8 bar) when the valves are forcibly opened. For any car with racing in mind, racing valve springs need to endure much more. Not uncommon are 200-300 psi (1.8 to 20.7 bar) with the valves closed and over 1000 psi (68.9 bar) during intake.

When Should Valve Springs be Replaced?

Springs must have enough pressure to prevent valve float, or when the springs are unable to close the valves properly, causing misfire or loss of power. If the springs are fatigued and too worn, then extended periods of valve float can lead to severe damage to the valves, pistons and camshaft and end in complete engine failure. Inspecting and testing the springs for the right pressure, and ensuring that they have no visible damage or are deformed goes a long way in maintaining good engine health. Springs that do have signs of advanced wear need to be promptly replaced.

How Valve Springs Impact Engine Performance

Valve springs have evolved in line with advancements in valvetrain designs and driver expectations of getting the most out of their cars. Springs have improved to allow for higher rates of valve lift, or the distance the valves can move in the intake and exhaust ports. More lift equates to more air for combustion, and more expended exhaust gases, so performance is also improved.

Another variable that will affect engine performance, though in a negative way, is coil bind. This occurs when the springs are fully compressed, and the individual coils are in contact with each other. The result is that the valve cannot open further. Coil bind can damage other valvetrain parts like the cam lobes, lifters, and rocker arms. To prevent this, specify the springs in the recommended height.

Valve Spring Shapes and Designs

The number of intertwining coils and how they have shaped means there is more than one type of valve spring.

Single Springs

Single springs are the oldest designs and are typically what you’d find in production cars. They come in three distinct variations. Standard valve springs consist of a single coil with a rubber damper inside. They’re adequate for daily driving, but won’t be good at higher stresses, since they generate more friction and heat, resulting in hastened wear when pushed harder. In addition, valve lift is not something to brag about, and the likelihood of valve float is increased.

Conical springs are another type of single valve spring, tapering in diameter from bottom to top. The design allows for more valve lift and better control of valve float. Cases of coil bind are also lower than in standard springs.

Beehive valve springs are a newer take on the single spring design and get their name from the tighter top end. These are sought-after racing valve springs that achieve more valve height, before encroaching on coil bind. Less material (with smaller retainers) and lower weight are needed at higher RPMs and help to prevent valve float.

Dual Springs

Dual valve springs have an inner and outer spring rubbing against each other. They consist of fewer coils than single springs allowing for more valve lift. These work wonders in heavier valve trains, like that in the Nissan RB in the early Skylines and Commodore, the Chevy LS1 in the Commodore VT Series II, and larger V8s with overhead cams. Conical dual valve springs are a recent addition and provide even better performance in stock engines.

Triple Springs

Three intertwining springs work best where there are extremely high forces acting on the springs and valves. Think typical racing applications and souped-up big block engines.

What to Look for in Valve Springs

Valve springs and valve train parts are some of the least understood engine parts. Novelties in designs and materials are relatively recent, though small changes can produce some interesting results. If you’re on the lookout for performance valve springs, there are a few things to consider:

• Spring Diameters – springs need to fit the cylinder head. The inner diameter is that of the innermost ring and labelled I.D., and the outer diameter (O.D.) is that of the outermost ring. If the O.D. is too big the spring won’t fit the seat, and if it is too small, it will move around. Additionally, if the I.D. is too small, it can interfere with the valve guide.

• Spring Height – heights determine spring pressure and prevent coil binding. Look for springs with compatible installed height, or the height of the spring, with the valve closed; and open height, with the valve open. The difference between the two is the available spring lift. Also, take into account coil bind height, or the height of the spring with the coils in contact with each other.

• Spring Pressure – springs with too low pressure will eventually lead to valve float, and high pressure will raise friction and heat and damage lobes, rocker arms, pushrods, and other parts. Two measurements are important here – seat and open pressure. Seat pressure is the force in the springs that holds the valves closed. Open pressure is the force pushing on the valve at the maximum rate of lift. The weight of the cams, lobes, lifters, and valves will dictate the pressure in the spring. Pressure and height determine the spring rate or the stiffness of the spring. Higher spring rates are preferred at higher RPMs, though a knock-on effect is advanced valvetrain wear.

For stock engines, go by manufacturer measurements and recommendations to get the best balance between performance and longevity. In racing uses and modified engines, get the springs that squeeze out all of the available power.