Industry

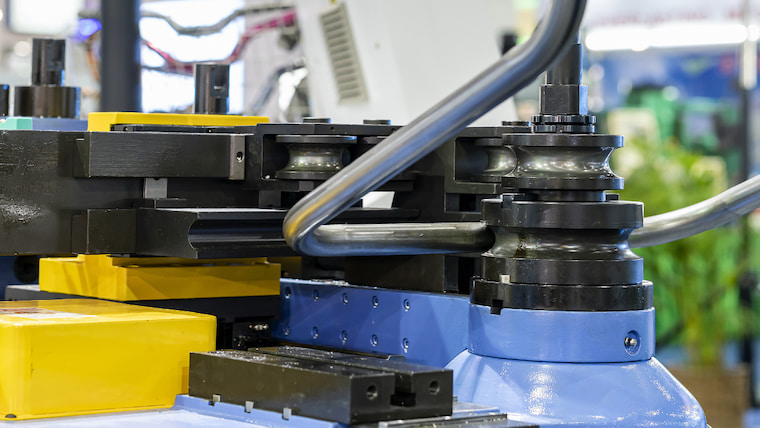

Revolutionizing Workshops: The Importance of Hydraulic Pipe Bending Machines

Hydraulic pipe bending machines have become indispensable tools in various workshops, playing a crucial role in shaping metal pipes with precision. Their significance extends beyond mere convenience, particularly in exhaust shops and other types of workshops. In this article, we will delve into the importance of hydraulic pipe bending machines, explore their applications in different workshops, emphasize the need for high-quality equipment, and provide insights into differentiating between a high-quality and a poor-quality hydraulic pipe bending machine.

Importance in Exhaust Shops

Exhaust shops are one of the primary beneficiaries of hydraulic pipe bending machines. These machines allow professionals to shape exhaust pipes with accuracy, meeting specific design requirements. The efficiency and precision of hydraulic bending machines contribute to the creation of exhaust systems that enhance the overall performance of vehicles. Whether it’s creating custom exhaust systems for performance vehicles or replacing damaged components, hydraulic pipe bending machines streamline the process, ensuring a perfect fit and optimal functionality.

Versatility in Various Workshops

Beyond exhaust shops, hydraulic pipe bending machines find applications in a wide range of workshops. Industries such as construction, manufacturing, and plumbing rely on these machines to bend pipes of different materials, sizes, and thicknesses. In construction, for instance, hydraulic pipe bending machines are used to create bends in pipes that are essential for structural frameworks and plumbing systems. The versatility of these machines makes them invaluable across diverse sectors, offering a cost-effective and time-efficient solution for bending pipes to desired specifications.

The Importance of High-Quality Hydraulic Pipe Bending Machines

Investing in a high-quality hydraulic pipe bending machine is paramount for workshop efficiency, cost-effectiveness, and the production of durable products. A reliable machine ensures precise bending without compromising the integrity of the material. Here are several reasons why opting for a high-quality hydraulic pipe bending machine is crucial:

Accuracy and Precision

High-quality machines are equipped with advanced technology and precision controls, allowing for accurate and consistent bending. This is especially important in workshops where precision is critical to meet specific design and structural requirements.

Durability and Longevity

A well-built hydraulic pipe bending machine is constructed with durable materials, ensuring longevity and minimal wear and tear. This not only reduces maintenance costs but also enhances the overall efficiency of the workshop.

Versatility

High-quality machines often come with features that enhance versatility. This includes the ability to bend pipes of various materials, sizes, and thicknesses, making the machine adaptable to different workshop requirements.

Safety

Safety is a top priority in any workshop. High-quality hydraulic pipe bending machines are designed with safety features to protect operators and prevent accidents. This includes emergency stop buttons, safety guards, and intuitive control interfaces.

Energy Efficiency

Modern hydraulic pipe bending machines are designed with energy-efficient mechanisms, reducing operational costs over time. Investing in a high-quality machine ensures that the workshop remains environmentally conscious and cost-effective.

Differentiating High Quality from Poor Quality:

When considering the purchase of a hydraulic pipe bending machine, it’s essential to differentiate between high-quality and poor-quality options. Here are key factors to consider:

Build Material and Construction

Examine the materials used in the construction of the machine. High-quality machines are often built with robust materials such as cast iron or high-grade steel, ensuring durability and stability during operation.

Technology and Controls

Evaluate the technological features and controls of the machine. High-quality machines incorporate advanced technology, offering precise control over the bending process. Look for user-friendly interfaces, digital displays, and programmable settings.

Manufacturer Reputation

Research the reputation of the manufacturer. Established and reputable manufacturers are more likely to produce high-quality machines. Customer reviews, industry certifications, and warranty offerings can provide insights into the reliability of the manufacturer.

Safety Features

Assess the safety features of the machine. High-quality machines prioritize operator safety with features such as emergency stop buttons, safety guards, and clear operating instructions. Ensure that the machine complies with safety standards and regulations.

Customer Support and Warranty

Consider the level of customer support and the warranty provided by the manufacturer. A reliable manufacturer stands behind their product with a comprehensive warranty and responsive customer support, ensuring peace of mind for the buyer.

Conclusion

In conclusion, hydraulic pipe bending machines have revolutionized the way workshops operate, providing efficiency and precision in shaping metal pipes. Their importance spans various industries, with exhaust shops and other workshops benefiting from their versatility. When investing in such a critical piece of equipment, prioritizing a high-quality hydraulic pipe bending machine is essential. The accuracy, durability, safety features, and manufacturer reputation are crucial factors to consider when purchasing. By understanding the significance of these machines and differentiating between high and poor-quality options, workshops can ensure optimal performance and long-term success in their metal fabrication endeavours.